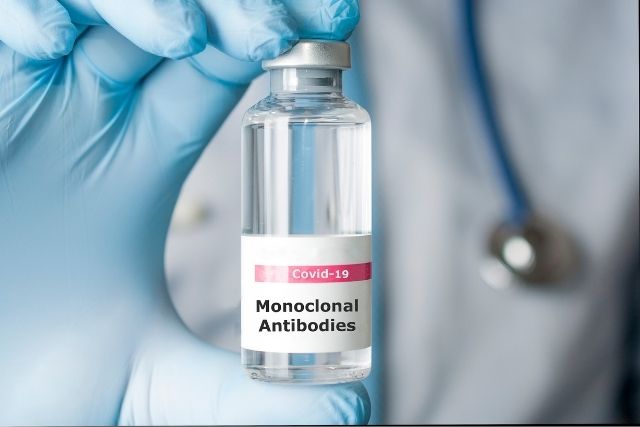

The efficacy of life-saving vaccines and temperature-sensitive medicines is highly critical in healthcare. Yet, this becomes more problematic as such are implemented in remote or resource-limited settings where electricity supply cannot be relied upon.

Here comes the marvelous solution:

Ice-Lined Refrigerators (ILRs):

The “Know-how”:

Contrary to traditional fridges that depend on a constant power source, ILRs operate on the principle of a thermos flask using ice as a cooling agent. The ice lining forms when a refrigerant solution flows through hollow channels within the walls of the refrigerator. As it goes by, this chilled solution freezes water against the walls into a thick sheet of ice.

This thick layer of insulation made from ice is capable of maintaining low temperatures and keeping cold for long hours with remarkable efficiency. A thermal buffer consisting of this thick layer prevents any fluctuations inside the fridge unit thereby ensuring that its temperature stays between 2°C to 8°C (36°F to 46°F), which is ideal for vaccine storage.

In areas where there’s no reliable source of power or during prolonged blackouts, such equipment still maintains cold temperatures.

The Extensive Use:

ILRs have been extensively deployed in remote parts, rural regions, health centers, community outreach projects as well as mobile vaccination campaigns especially in underdeveloped countries or places with poor infrastructure. Their transportability and low energy consumption make them invaluable devices during humanitarian missions and disaster relief activities where essential medical supplies preservation is mandatory.

Design Fortes:

Aside from their practical uses, ILRs have an impressive set of characteristics that make them efficient for harsh environments. Their passive cooling system ensures savings on costs without reliance on electricity for cooling purposes and with minimum need to maintain them. Also, many ILR models are ruggedized for tough handling and environmental conditions.

Such units meet international norms set by institutions like WHO – World Health Organization and CDC– Centers for Disease Control & Prevention thus strengthening trustworthiness and safety of these vaccine storage refrigerators. In a world where healthcare is a global challenge, ILRs remain the only hope that life-saving vaccines can be maintained efficient even in the most distant corners of the earth. They are an example of creative engineering at its zenith in terms of bridging recent medical advances with limitations imposed by lack of resources to guarantee safety and health for many individuals in the world.

About Us:

M/s. Rockwell Industries Limited, we are the leading manufacturers of commercial, medical and cold chain equipment in India since 1986. With a rich legacy of 37 years, the company takes pride in being one of the first institutions to bring out CFC-free refrigeration solutions in Indian market.

Rockwell owns two state-of-the-art manufacturing facilities in Hyderabad, covering 2,00,000 square feet that has annual production capacity which exceeds over 4,00,000 pieces of equipment units. Rigorous quality standards are maintained by the company through its robust R&D team and NABL accredited type test lab with temperature and humidity control.

Rockwell has prestigious certificates like ISO 9001, ISO 14001, ISO 13485, ISO 20000-1, ISO 45001 and ISO 50001. A well spread network of 12 branches and more than 500 trade partners enable the company to have nationwide presence.

The countrywide operations network comprises of a total of 374 service centers alongside 1174 highly skilled technicians to make sure there is no disruption whatsoever. Our impressive clientele includes names such as UNICEF, Coke, Pepsi, Vadilal, Amul, Dr Reddy’s, CIPLA, Apollo, Elbit, Medical Health Animal Husbandry Departments from various states Indian Railways, Indian Air Force, IIT Mumbai, IIT Bhilai etc.