Patient safety is the top priority for Intensive Care Units (ICUs). Critical safety challenges include the prevention of infections. A multitude of Infection control strategies proves that the design and material of respiratory support equipment is most crucial. One notable enhancement is the use of medical-grade silicone in place of the traditional PVC for ventilator circuit tubing.

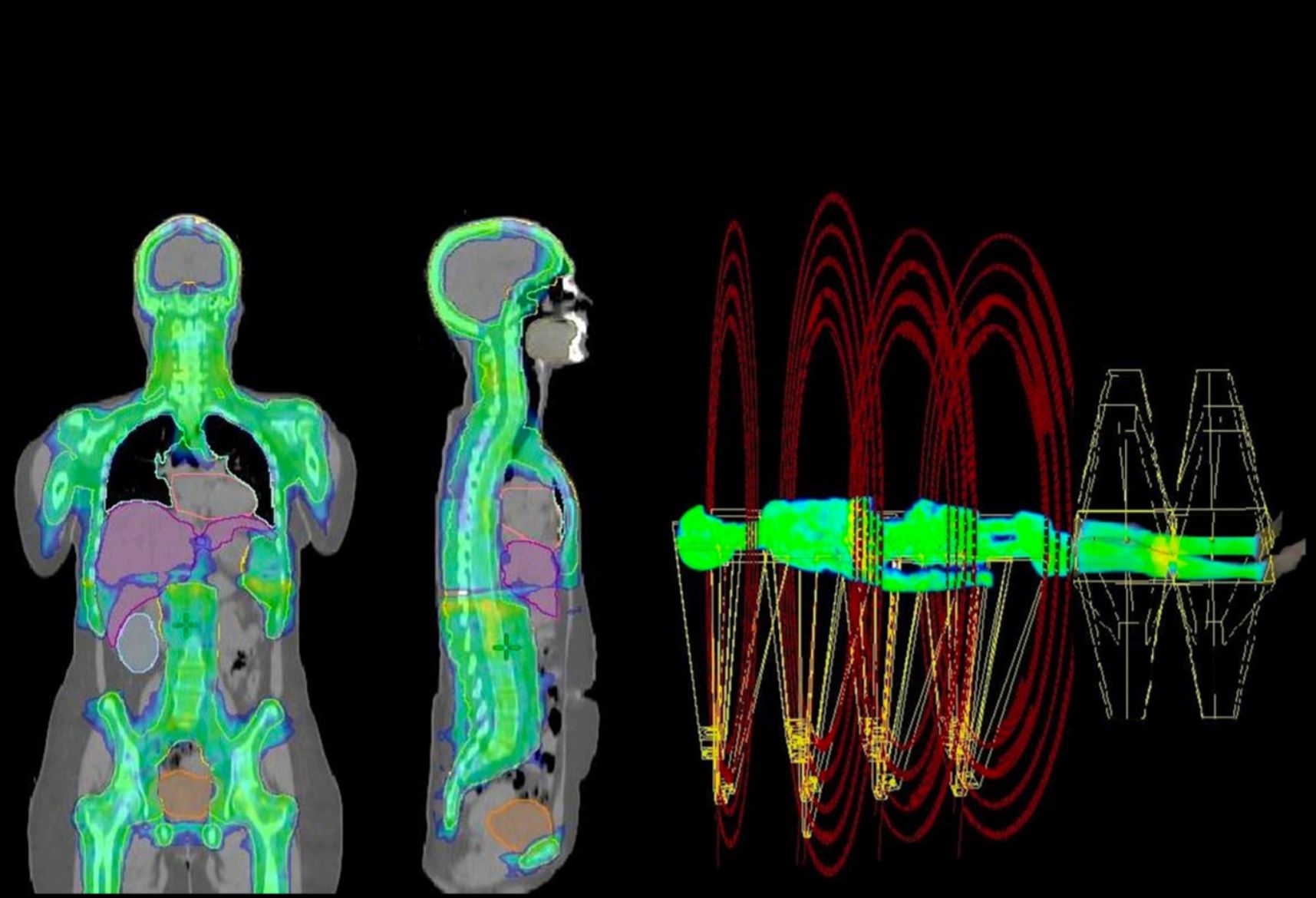

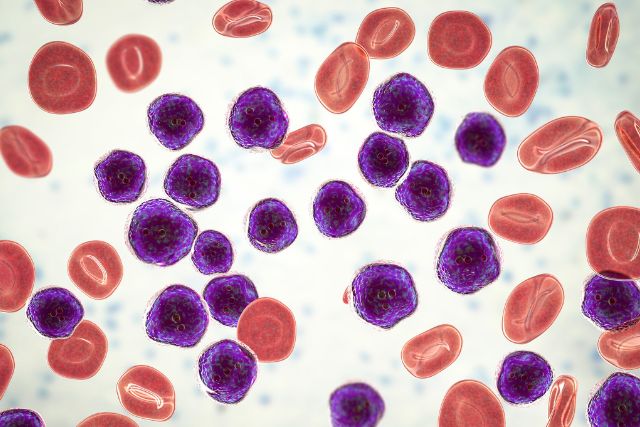

ICU VENTILATOR-ASSOCIATED PNEUMONIA (HAIS VAP)

Ventilator-Associated Pneumonia (VAP) is one of the many healthcare-associated infections that plague the Intensive Care Units (ICUs). VAP is usually the result of the colonization of pathogenic bacteria in the airway or in the tubing of the ventilator. The risk of infection is proportional to the length of the intubation period. It can be concluded that less aggressive tubing and materials can prevent infection and improve the quality of care.

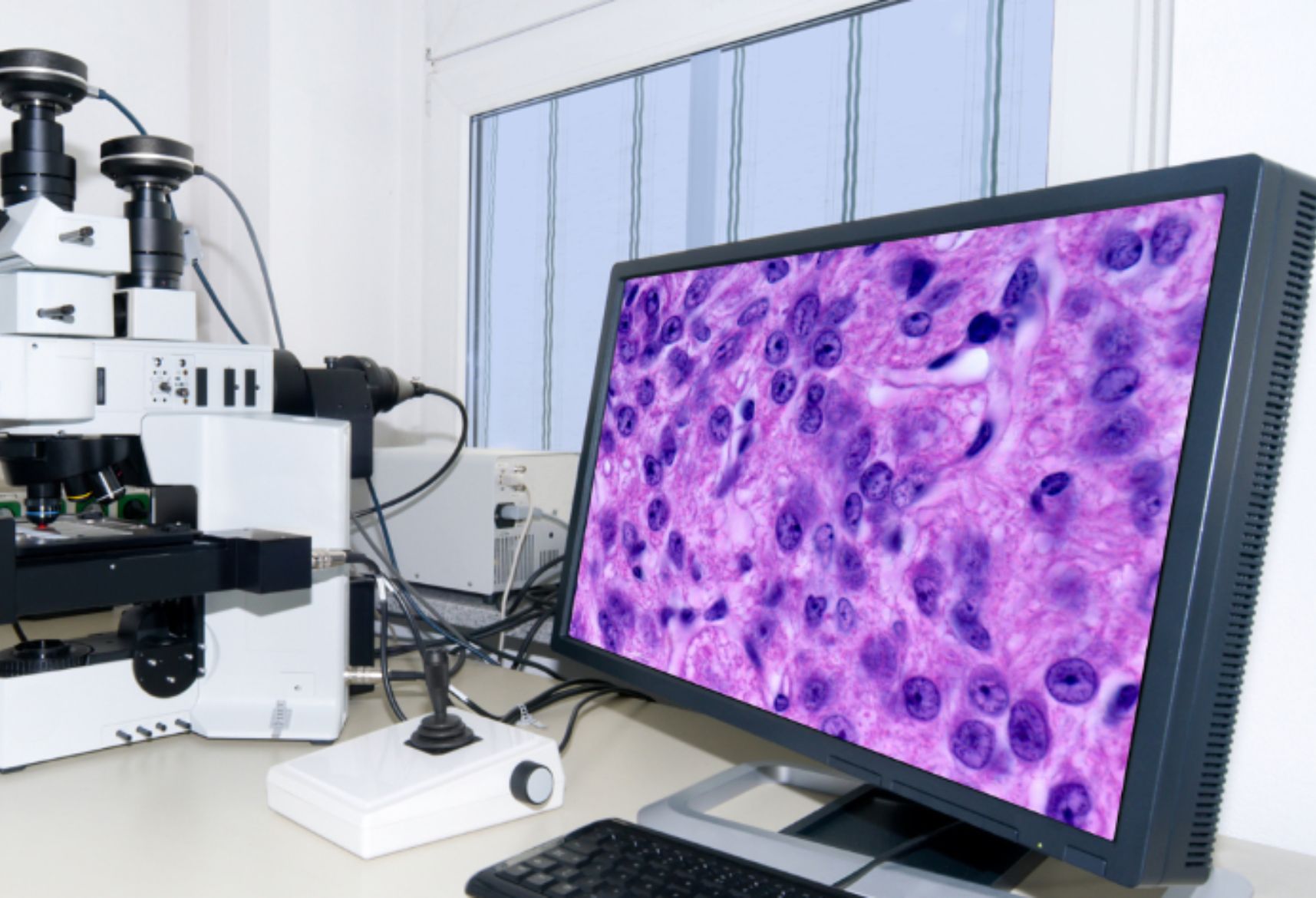

WHY SILICONE? THE SIGNIFICANCE OF THE MATERIAL

Silicone, particularly platinum-cured medical silicone, has many unique qualities that substantiate its use in the manufacturing of ventilator circuit tubes.

- Biocompatibility: Medical silicone is non-toxic, hypo-allergenic, and safe for prolonged contact with patient tissues.

- Inner Surface: Medical silicone has a smooth inner surface which minimizes bacterial colonization and increases the risk of biofilm formation.

- Thermal Stability: Medical silicone can withstand multiple sterilization cycles (autoclave, ETO, gamma).

- Shape integrity: Silicone retains its memory and is flexible.

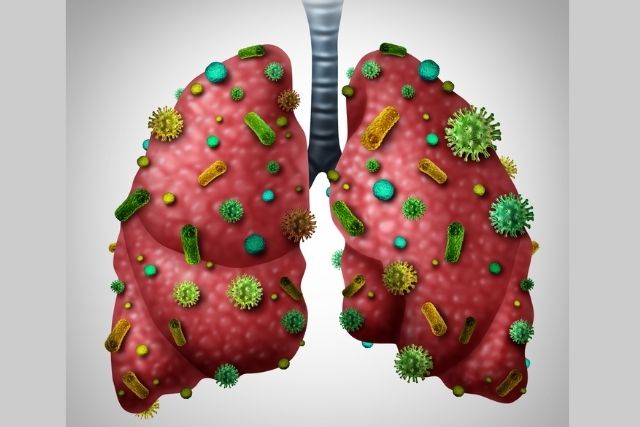

- Silicone Ventilator Tubing and Infection Control

Less Microbial Growth

Due to the smooth and chemically inert structure of the silicone, the adhesion of pathogens is lesser. This is critical for closed-loop ventilator systems where the moisture and secretions can lead to contamination.

Better Reusability

Silicone has the ability to withstand sterilization procedures which is not the case with PVC. This aids silicone in being sustainable, reusable, and lowers the cross-infection risk in the clinical setting.

Better Control of Airway Humidity

Silicone tubing has superior insulating properties which promote the ventilation of moisture, thereby supporting the health of the airways.

Customization & Tubing Connections

Silicone tubing offers tight and custom-fitting connections to help ensure that air leaks do not occur. This reduces the frequency of required adjustments to the tubing which can expose the circuit to contaminants.

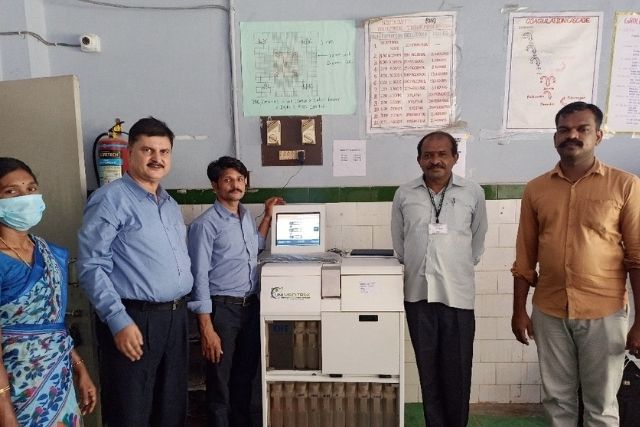

Applications in Modern ICU Setups

- Mechanical ventilators (invasive and non-invasive) CPAP/BiPAP machines

- Anesthesia machines

- High-flow oxygen therapy systems

Why Choose AMI Polymer’s Silicone Ventilator Circuit Tubing?

At Ami Polymer Pvt. Ltd., our silicone ventilator circuit tubing is:

- Manufactured using USP Class VI & ISO 10993 compliant silicone

- Available in customized size

- Designed for custom connector fittings

- Compatible with both reusable and disposable setups

- Produced under ISO 13485 certified cleanroom conditions

- Soft, Flexible Design: Minimizes discomfort during long-term use.

- 100% Medical-Grade Silicone: Ensures exceptional biocompatibility, flexibility, and durability.

- Sterile Packaging: Our products are packed in sterile, individually-sealed packaging to maintain hygiene and ensure safety during use.

We offer tailor-made solutions for OEMs, hospitals, and device manufacturers seeking advanced respiratory components that align with infection control protocols.